Ultra High Resistance Meter

5450/ 5451

- High resolution of 5½-digit display

- Micro current measurement: 1 fA to 19.9999 mA

- High-resistance measurement: 3 x 1017 Ω (current function)

- Voltage source: ±1 mV to ±1000 V

- High-speed measurement: up to 1000 readings/s

- Floating measurement of 1000 V (5450)

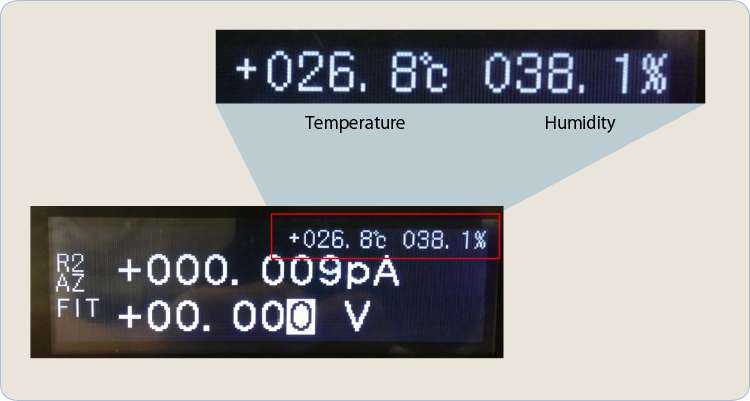

- Temperature and humidity measurement

(with the optional accessory) - Preset function for easy measurement condition setting

- Sequence program for routine measurement

The 5450/5451 is a state-of-the-art ultra high resistance meter with 5½-digit display that integrates ADC’s traditional technologies and new DC amplifier technologies. It was designed for ease of use so that anybody who operates this instrument can get the same measurement results. The 5450/5451 will be the new standard for insulation resistance measurement or micro current measurement of various kinds of insulating materials or semiconductors.

Such a high-performance instrument, 5450/5451 is used in testing of secondary cell and semiconductor materials or testing of electronic parts such as capacitors and print-circuited boards. In addition, it can be used in various usages for insulating materials such as synthetic resins and rubbers from R&D, manufacturing to quality inspection fields.

Features

High performance and high speed

The 5450/5451 is a high-performance meter capable of measuring micro current from 1fA to 19.9999mA and high resistance up to 3×1017 Ω(in current function). In addition, with its high-speed sampling capability up to 1000 readings per second, the 5450/5451 is suitable for Go/No-Go test in electronic part manufacturing.

5450 or 5451 depending on the DUT status

|

5450 |

✓ | ✓ |

| 5451 | N/A | ✓ |

| DUT status and connection diagram |  |

|

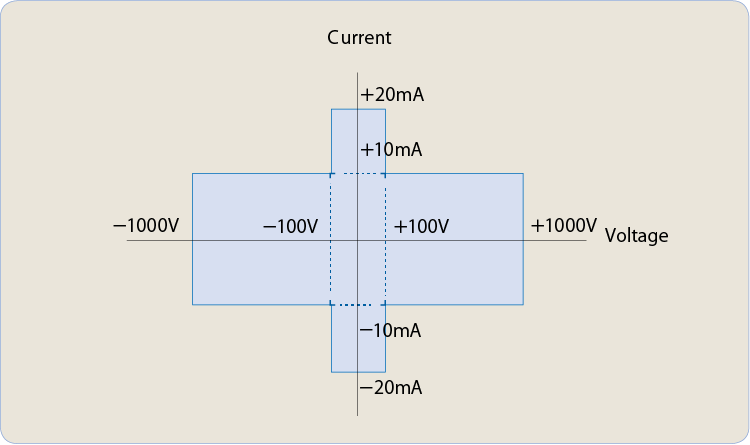

Powerful and flexible voltage source

As internal voltage source, a power supply that is capable of current source and sink up to 10 W at ±1000 V was newly developed. This new power supply also applies negative voltage. Thus, the 5450/5451 can not only measure p-channel and n-channel semiconductors or avalanche photo diodes (APD) that operate with reverse bias voltage, but also help capacitors to be charged or discharged quickly.

In addition, by setting the current limit values at will, devices are protected from overcurrent due to breakdown in semiconductor evaluation.

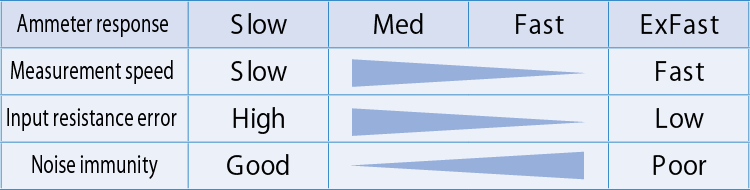

Selectable ammeter response

Actual ultra-high resistance measurement or micro current measurement is sometimes difficult to make under the influence of the ambient noise environment. However, a need exists for high-speed measurement in a noise-proof environment.

To satisfy demands for various purposes, the 5450/5451 employs the variable gain feedback system and the response speed of the ammeter is selectable. Consequently, there is a choice between measurement highly durable against disturbance noise and high-speed measurement with quick response depending on the application or required accuracy, thus ensuring highly reliable measurement.

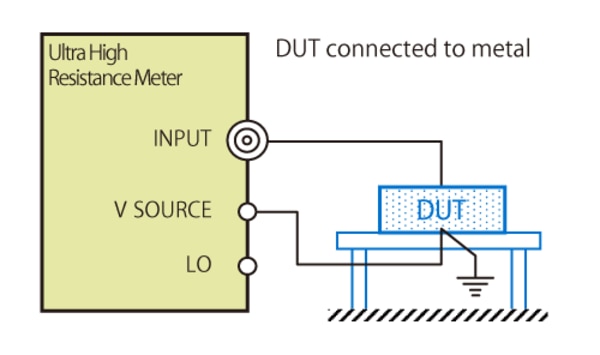

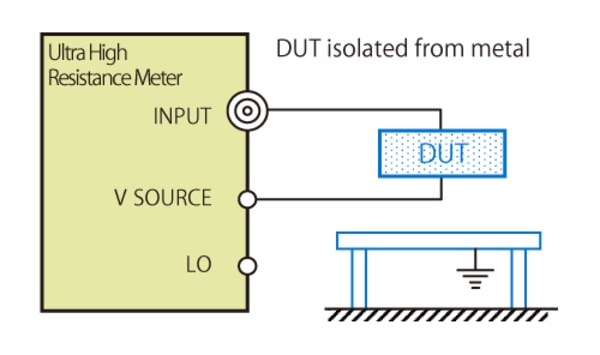

Stable measurement of grounded sample

The 5450/5451 is capable of floating measurement. The 5451 has floating measurement capability up to 46 V peak, however the 5450 up to 1000 V peak that enables a DUT grounded at one side to be measured.

Temperature and humidity measurement

JIS K6911 and K6723 specify temperature and humidity as test conditions for material resistivity measurement. The 5450/5451 can measure the ambient temperature and humidity by connecting the recommended temperature/humidity sensor probe.

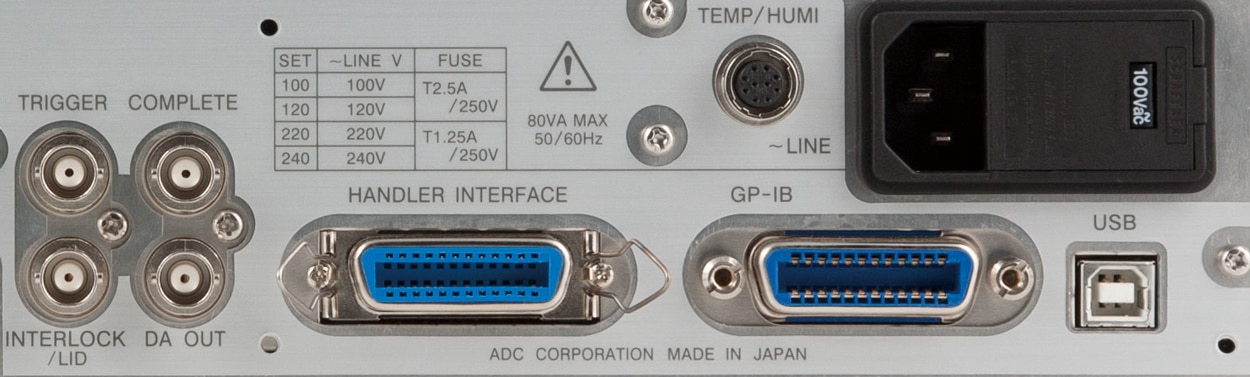

Interface selection

In addition to GPIB and USB, the 5450/5451 is equipped with a handler interface that can control the timing with external devices such as a automatic machine in a production line. Moreover, the embedded interlock signal prevents unintended voltage output to help operators perform safety measurement.

Preset function for quick operation

For ultra-high resistance or micro current measurement, the amplifier gain, the integration time and the input resistance need to be set according to its purpose. For surface or volume resistivity measurement, the electrode coefficient needs to be set. Like this, various settings are required before measurement.

The 5450/5451 contains ten types of preset conditions for surface or volume resistivity measurement using the accessory, micro current measurement by pico ammeter, capacitor leak current measurement and other measurements. Thus, such a measurement can be started quickly by just selecting the preset condition without long condition settings.

Of course, user parameter settings are also available

【Preset Parameters For Applications】

| Application | Description | |

| High-speed current measurement |

For pico-ammeter usage. Setting for high-speed micro current measurement. |

|

| R measurement | Les than 0.04 μF | Setting for less than 0.04 μF capacitor IR measurement |

| 0.04 μF to 4 μF |

Setting for 0.04 μF to 4 μF capacitor IR measurement |

|

| More than 4 μF |

Setting for more than 4 μF capacitor IR measurement |

|

| JIS measurement | K6911 |

For Φ50 electrodes. |

| K6723 |

For Φ70 electrodes. |

|

| C2170 |

For Φ30.5 electrodes. |

|

| 12707 liquid electrode |

Setting for volume resistivity measurement of liquid crystal materials. |

|

| Insulation resistance measurement | High-noise immunity setting for measurement of high-resistance materials under an unshielded environment. The source voltage setting is required. | |

| Input resistance 1 kΩ |

The input resistance is 1 kΩregardless of the measurement range. |

|

Sequence program function

The 5450/5451 has a sequence program function to store seven patterns of sequence such as order and conditions of measurements.

This function makes it possible to easily measure insulation resistance one minute after voltage application conforming to JIS.

In addition, anyone can obtain the same measurement results by using the stored setting conditions.。

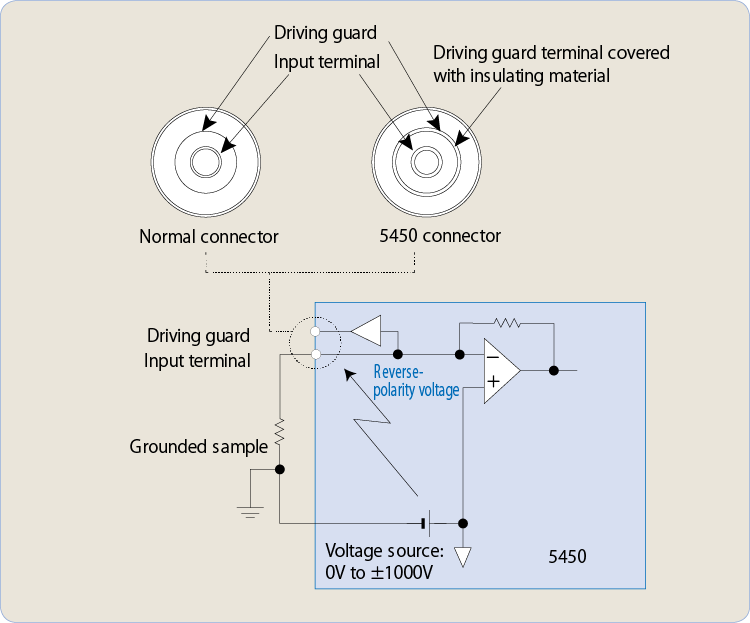

Much safer input connector

When insulation resistance is measured by using floating measurement, voltage of the reverse polarity to the setting voltage is generated between the input terminal and the driving guard. Conventional triaxial connectors are not necessarily safe because their metal parts are exposed. The 5450 adopts safer triaxial (S-Triax) connectors, securing measurement.

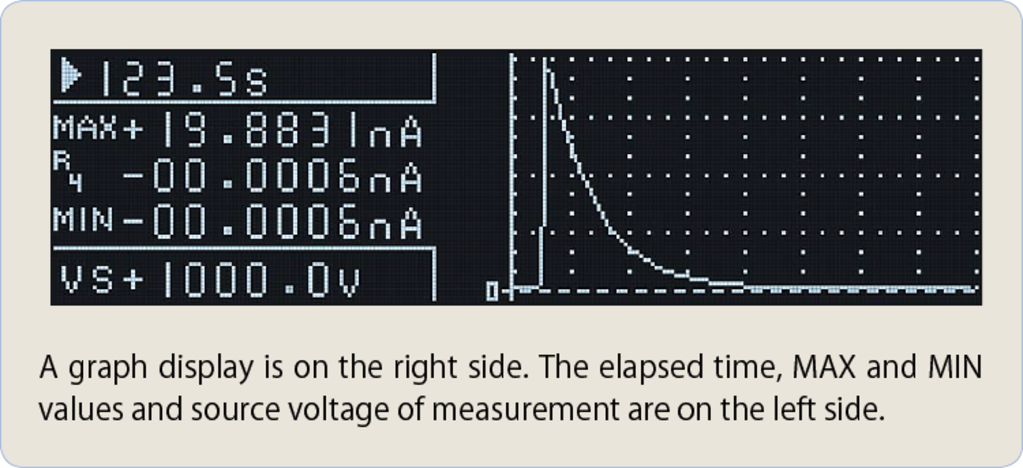

Graphical display of time course

When the leak current of a capacitor is measured, right after DC voltage is applied, inrush current that is called charge current corresponding to the capacity flows then it decreases exponentially. This current is called absorption current that is caused by the time change during dielectric polarization inside the sample. A current flowing after the absorption current reaches equilibrium becomes leak current. Here, the time it takes the absorption current to decrease exponentially and settle into equilibrium varies depending on the dielectric materials, and is sometimes very long. To measure the leak current precisely, it is important to see if the abruption current settles down. The 5450/5451 has a function to display the time course of measured values graphically on the dot-matrix LCD display. Thus, the measured values described above can be captured visually

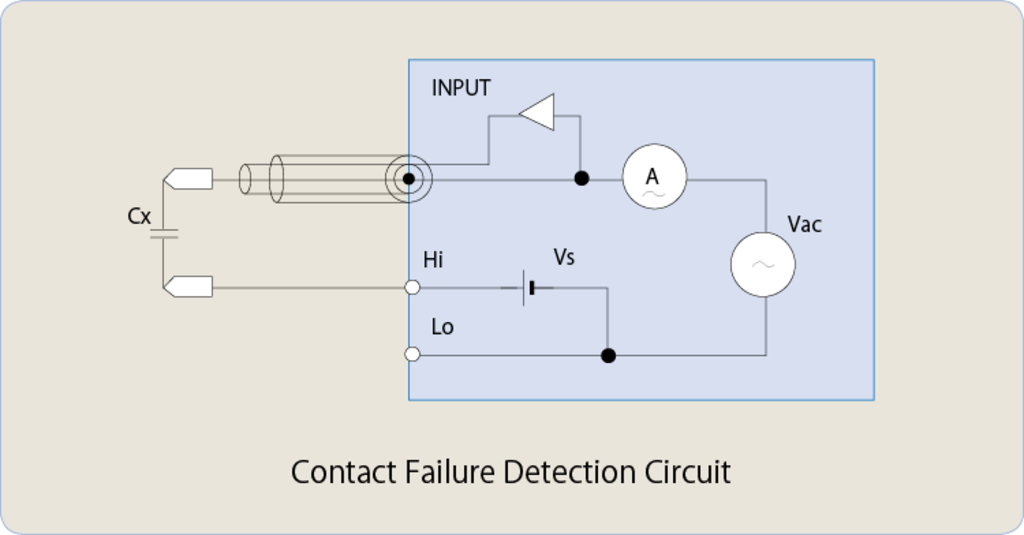

Contact check function

The 5450/5451 has a contact check function to detect quickly contact failures between capacitive samples (capacitors) and measurement cables or measurement electrodes. This function is executable when specified or in every measurement. Preceding Open Cal (default value measurement) cancels the capacity of the measurement cables or measurement electrodes, allowing precise contact check.

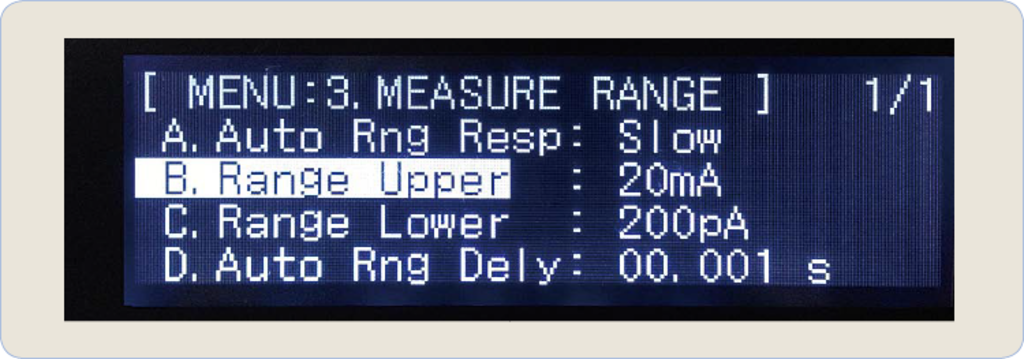

High-speed measurement in auto range

Thus, to improve the takt time, a fixed range mode is normally used for measurement.

However, the upper and lower limits of an auto range can be set on the 5450/5451. Consequently, setting the minimum necessary auto range realizes the minimum switching time and improves the takt time significantly

Applications

Condition setting with one touch

To measure the volume or surface resistivity of an insulating material, the electrode size needs to be set according to JIS. The preset function of the 5450/5451 includes the default settings of typical electrode sizes that are widely used, making it simple to set measurement conditions for various insulating materials.

| JIS No. | Electrode size | JIS titile |

| K6911 | φ50 | Testing methods for thermosetting plastics |

| K6723 | φ70 | Plasticized polyvinyl chloride compounds |

| C2170 | φ30.5 | Methods of test for determining the resistance and resistivity of solid planar materials used to avoid electrostatic charge accumulation |

Measurement with voltage source of ±1000 V

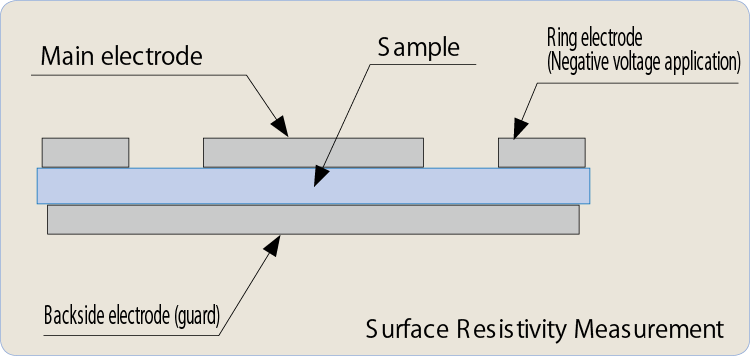

JIS K6911 is the measurement standard for the volume or surface resistivity of insulating materials such as plastic. As for the surface resistivity measurement, it specifies that negative voltage should be applied to the ring electrode against the main electrode. As the 5450/5451 is equipped with the bipolar voltage source that outputs both positive and negative voltage up to ±1000 V, it can measure precisely the surface resistivity

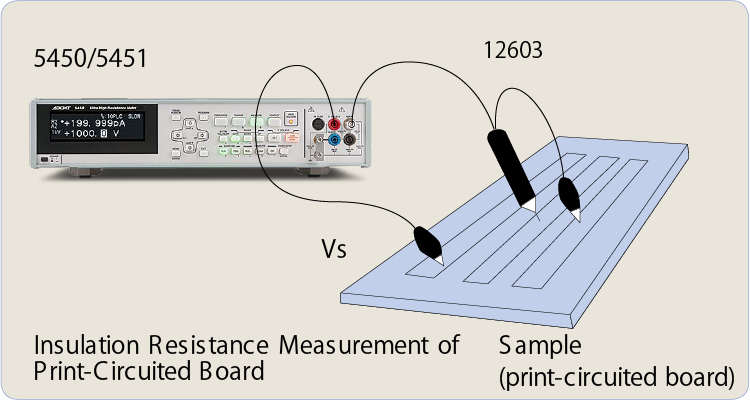

Print-circuited board resistance measurement

By using the accessory, test lead 12603, the insulation resistance of print-circuited boards can be measured.

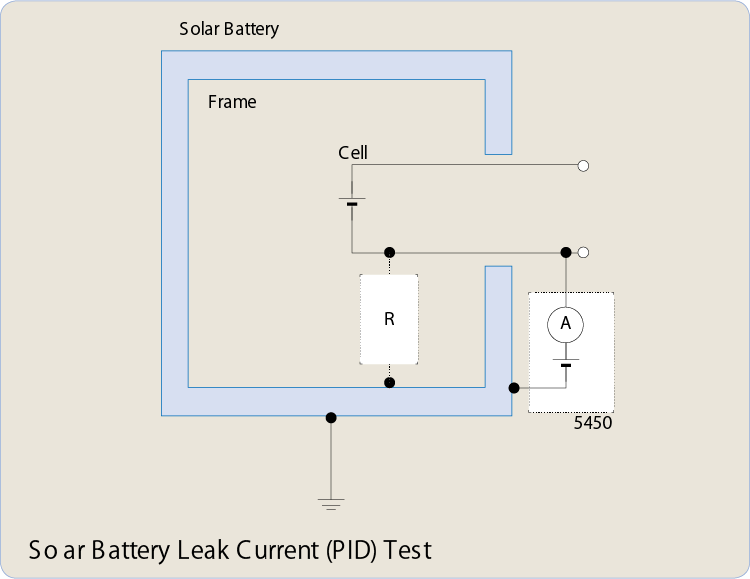

Solar battery leak current (PID) test

Solar batteries used in “Mega” solar power plants have a problem of output reduction called PID (potential-induced degradation) phenomenon in hot and humid conditions because leak current occurs in the module circuits at high voltage source. The PID phenomenon occurs by interaction among the tempered glass on the surface, cell, back sheet and the aluminum frame of a solar battery. To evaluate this phenomenon, the leak current between the cell and frame needs to be measured. Differently from the cell, negative voltage must be applied to the grounded frame. Thus, the 5450 capable of floating measurement of - 1000 V is the best choice.

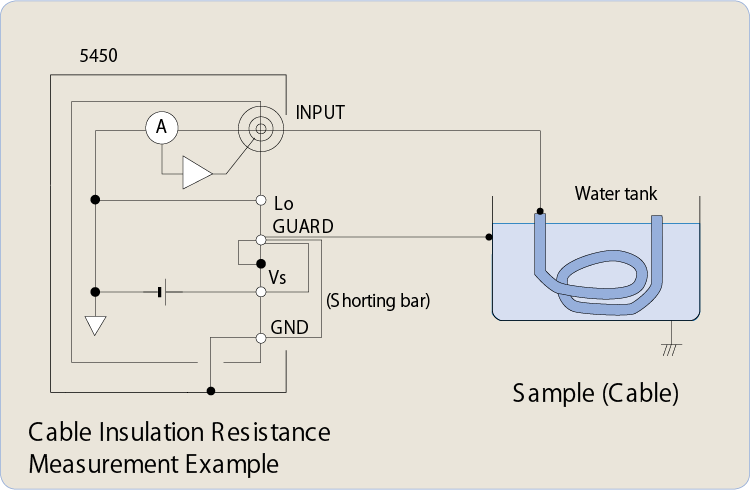

Cable insulation resistance measurement

The 5450 is capable of floating measurement up to 1000 DCV. Thus, it is suitable for measuring the insulation resistance of grounded cables, transformers and so on.

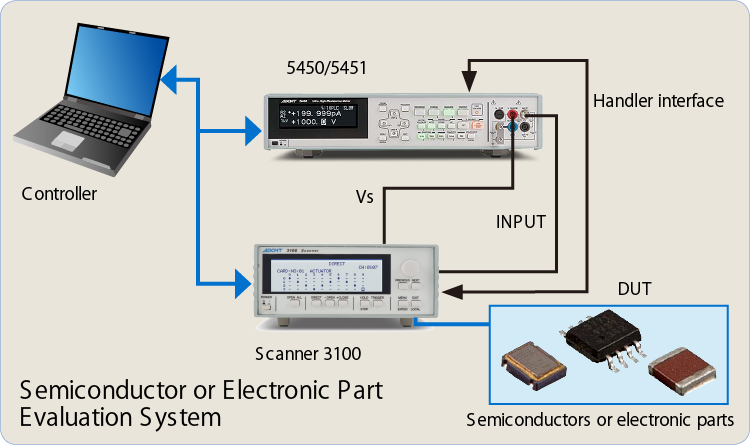

Electronic part evaluation system

The 5450/5451 not only performs high-speed measurement of up to 1000 readings per second, but also features the 65,000 data memory and the handler interface. The 5450/5451 shows its excellent performance by connecting with a scanner or a handler via a PC, for example in automatic sorting of semiconductors or electronic parts.

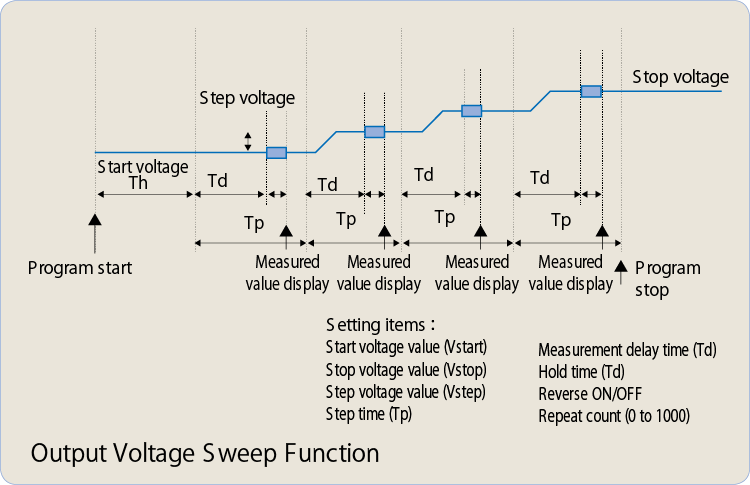

Pressure test by sweep function of ±1000 V

The 5450/5451 has a sequence program function that can sweep with a 4-digit setting resolution up to ±1000V. Using this function enables precise pressure test of semiconductors.

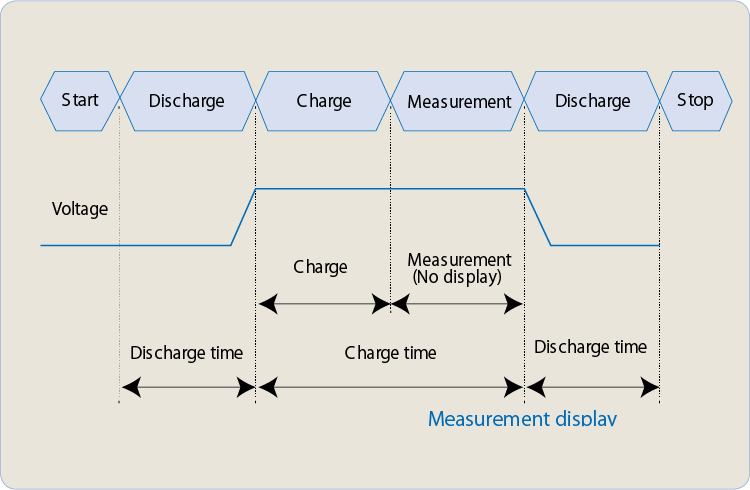

A Variety of Accessories for Research and Development of New Materials

Using the accessory resistivity chambers makes it easy to measure the volume or surface resistivity of materials. With the sequential program function and the LID signal, the 5450/5451 automatically performs discharge, charged and measurement according to the setting procedure in cover’s open and close timings.

Once the measurement conditions are set, the 5450/5451 always performs the same measurement. It can prevent measurement failures due to operational mistakes to occur. Electrode coefficients necessary for volume or surface resistivity measurement can be set in addition to those of the resistivity chambers.

- Leak current measurement and insulation resistance measurement of switches and relays

- Insulation resistnace measurement of capacitors and cables

- Insulation resistance measurement of printed-circuit boards

- Volume or surface resistivity measurement

(The 15702, 12704A or 12708 is used.) - Films (Mylar, plastics and papers)

- Glasses, ceramics and rubbers

- Insulating oil and varnish

- Semiconductor materils, and other materials

Resistivity chambers and test fixtures suitable for these measurements are available.

For more information, see below.

For measurement of the volume or surface resistivity of sheet, filmy and platy samples.

Pressure on samples is adjustable and thickness measurement is possible.

For measurement of the volume resistivity of liquid.

It requires only 0.8 cc of sample for measurement. The electrodes can be removed and cleaned easily.

For current measurement of semiconductors and other electronic components.

Current measurement in a wide range from 10-14A to 20A is possible.

Specifications

| Maximum display | 5½ | |

| Voltage measurement | Measurement method |

Variable gain feedback |

| Range | 1 fA to 20 mA | |

| Resistance measurement | Measurement method | Voltage application |

| Range |

10 Ω to 3×1017 Ω |

|

| Voltage source | Range | ±1000 V |

| Resolution | 1 mV | |

| 1000 V floating measurement |

Available (5450 only) |

|

| Sampling speed | 1000 readings/s | |

| Sequence function | Available | |

| Interface | GPIB, USB | |

| BCD OUTPUT | Factory option | |

| Handler IF |

Available |

|

| D/A OUTPUT | Available | |

*For the detailed specifications, please download the brochure from "Download."

Optional Accessories

Accessories for electrometers

15702

Resistivity Chamber

Application: Measurement of the volume or surface resistivity of sheet, filmy and platy samples

Feature: Pressure on samples is adjustable and thickness measurement is possible. Electrodes applicable to the JIS and ASTM standards are available.

12704A

Resistivity Chamber

Application: Measurement of the volume or surface resistivity of sheet, filmy and platy samples

Feature: Adhesion with the sample is excellent because all electrodes use conductive rubber.

12708

Resistivity Chamber

Application: Measurement of the volume or surface resistivity of sheet, filmy and platy samples

Feature: Capable of temperature application from ambient temperature to 200 ℃ to samples

15042

Resistivity Chamber

Application: Measurement of the volume or surface resistivity of sheet, filmy and platy samples

Feature: For general usage

12707

Test Fixture

Application: Measurement of the volume resistivity of liquid

Feature: It requires only 0.8 cc of sample for measurement. The electrodes can be removed and cleaned easily.

Test Fixture

Application: Measurement of the insulation resistance or micro current of capacitors and other electronic components

Feature: It has a structure that takes shielding and isolation into account, allowing stable measurement of low current and high resistance.

Test Fixture

Application: Current measurement of semiconductors and other electronic components.

Feature: Current measurement in a wide range from 10-14A to 20A is possible.

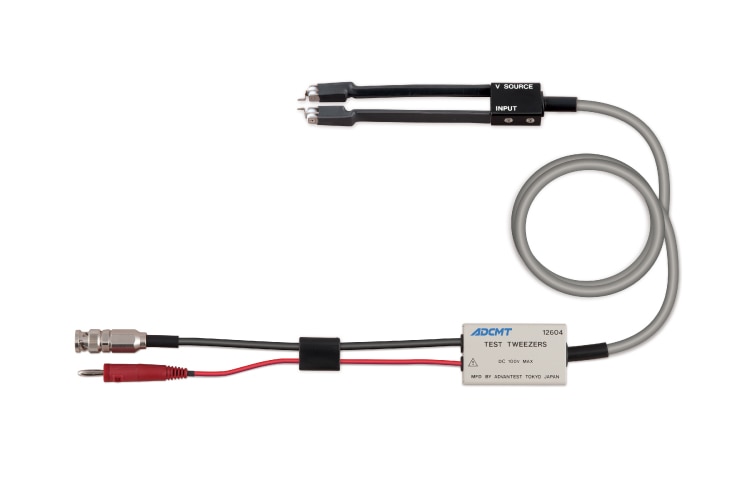

Tweezers Probe

Application: Measurement of the insulation resistance of chip capacitors

Feature: With the tweezers-like shape, small chip components can be measured easily and efficiently.

Shielded Measurement Plate

Application: To be used with the 12604 for exernal noise reduction

Feature: Teflon-coated shielded plate used with the 12604 for measurement with little inductive noise noise

Test Lead

Application: Measurment of the insulation resistance, voltage or current between pattens on PCBs.

Feature: Suitable for measurment which the measurement points are changed one after another. An external power source is required for insulation resistance measurement.

Voltage Divider Probe

Application: Measurement of high voltage with high impedance

Feature: Thanks to the division ratio of 100:1, the 5350 can measure up to 2 kV.

Standard Resistor

Application: Inspection of digital electrometers

Feature: Five types available: 1×108 Ω, 1×109 Ω, 1×1010 Ω, 1×1011 Ω and 1×1012 Ω

Cables and other accessories

| NamePart Number | Part Number |

| Input cable (S.TRIAX-high voltage TRIAX) | CC010004 |

| Output cable (safety-sefety, red, 2 m) | CC010007 |

| S.TRIAX-S.TRIAX cable | CC010008 |

| Input cable (TRIAX-TRIAX) | A01009 |

| Input cable (TRIAX-BNC) | A01011 |

| Input cable (TRIAX-alligator clip, high-voltage) *For the 5450, CC015003 is required. | A01018-100 |

| Input cable (BNC-BNC 1.5 m) | A01036-1500 |

| Input and output cable (safety plug) | A01044 |

| Input cable (high-voltage TRIAX-TRIAX) *For the 5450, CC015003 is required. | A01239 |

| Connector (TRIAXJ-TRIAXJ) | |

| Connector (TRIAXJ-BNCP) | A04203 |

| Connector (BNCJ-MP) | |

|

Connector (TRIAXJ receptacle) |

A04208 |

| Connector (S.TRIAX-high voltage TIRAXJ) | CC015003 |

| Connector (BNCJ-TRIAXP adapter) | CC015006 |

| Input cable (BNC-alligator clip) | |

|

Banana tip adapter (for A01044, CC010003 and CC010005) |

A08531 |

|

Rack mount set (2U JIS) |

CC022002 |

|

Rack mount set (2U EIA) |

CC024002 |

|

Front handle set (2U) |

CC028002 |

Download

Sample programs described on the Operation Manual

*Go to the download page.